8 560,00 €*

Immédiatement disponible, délai de livraison 5 - 7 Tage (10 - 12 Tage bei Versand ins Ausland)

⛏️ From our own production

☝️ 30 years of experience

✔️Inklusive Integrated pump chamber

Maximum flow rate:

Pumped version: approx. 70 m³ / hr.

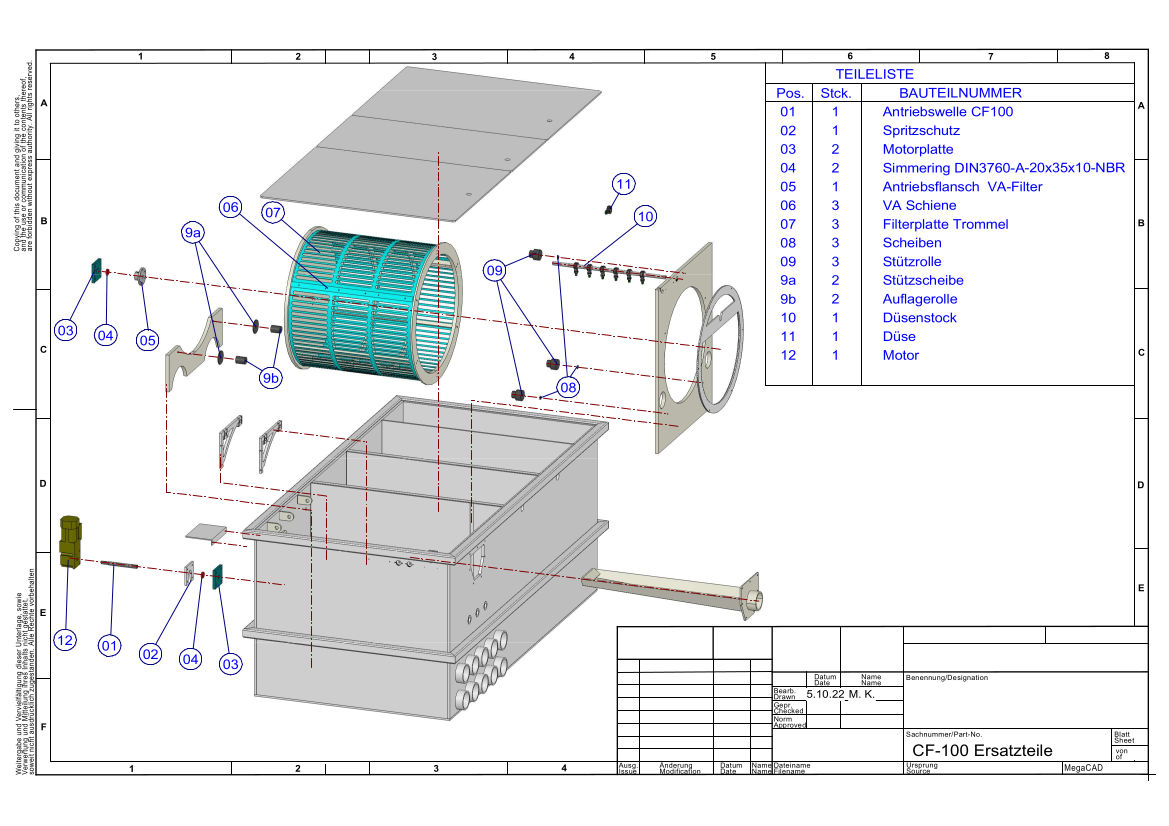

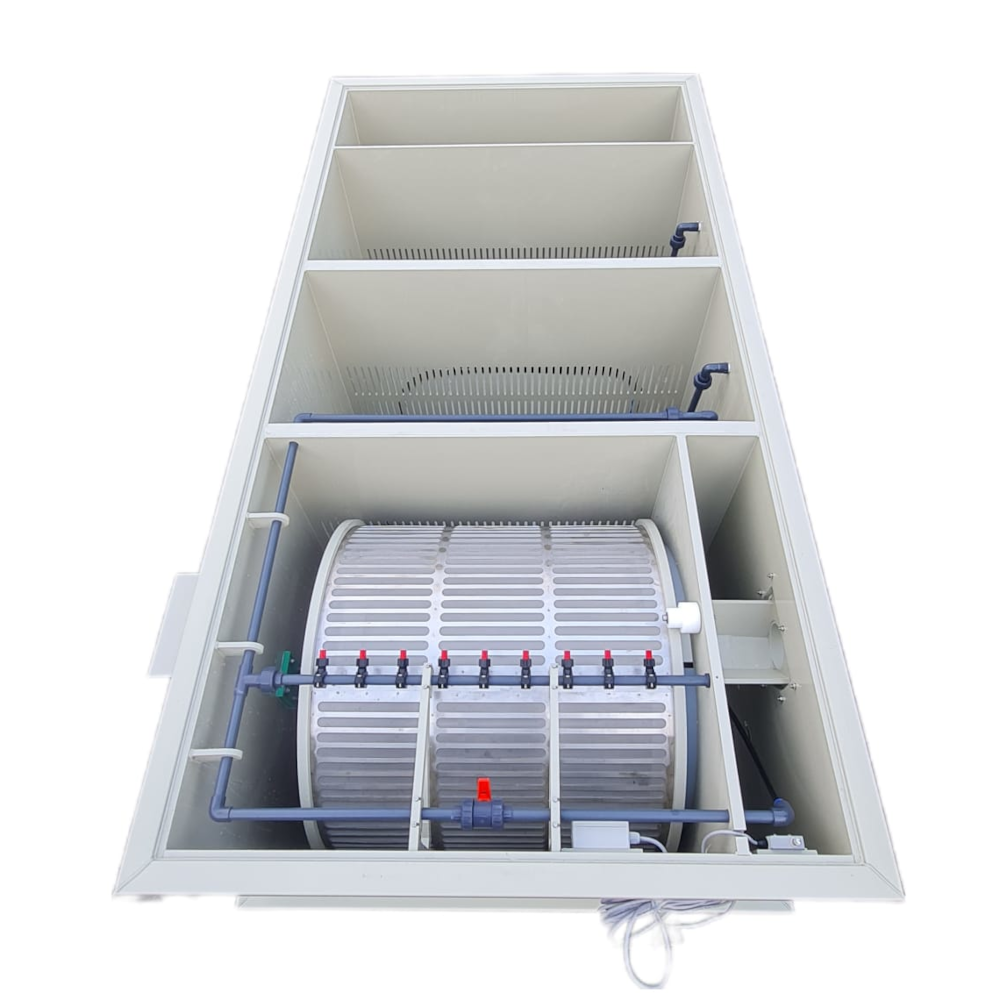

Technical data:

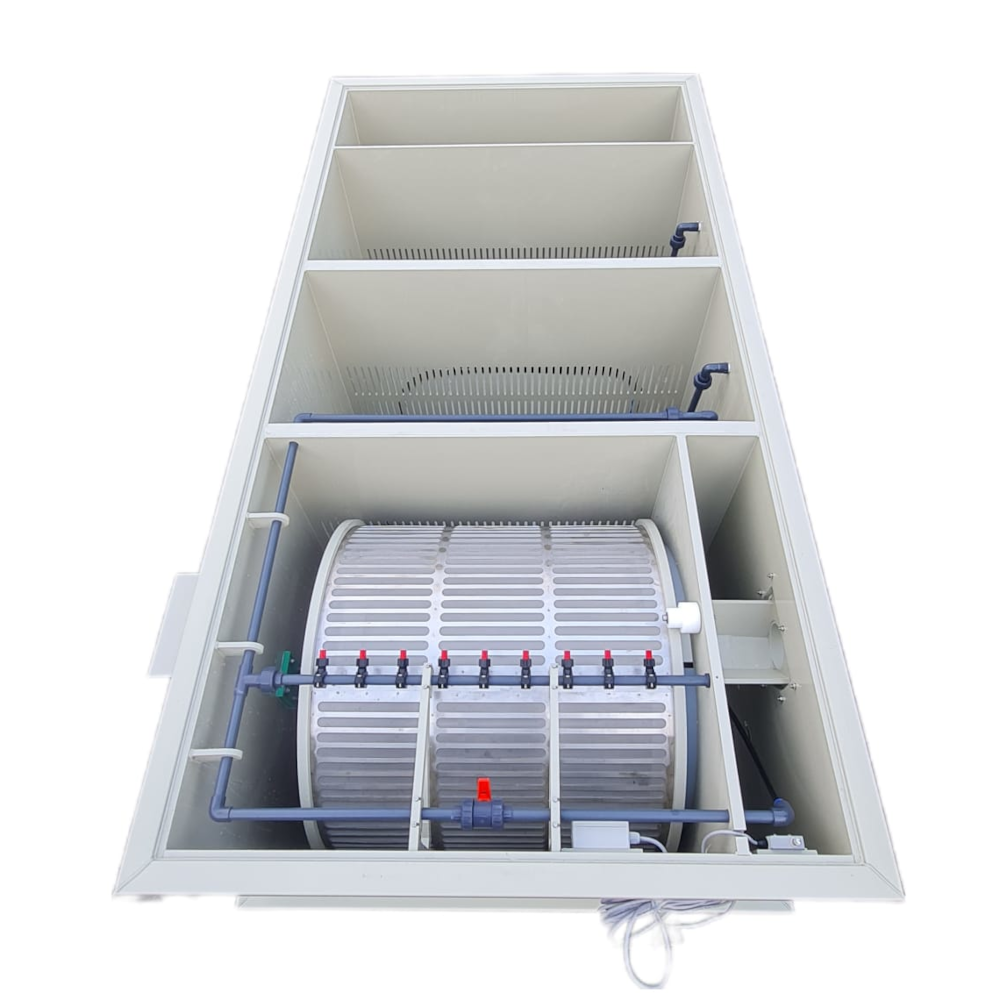

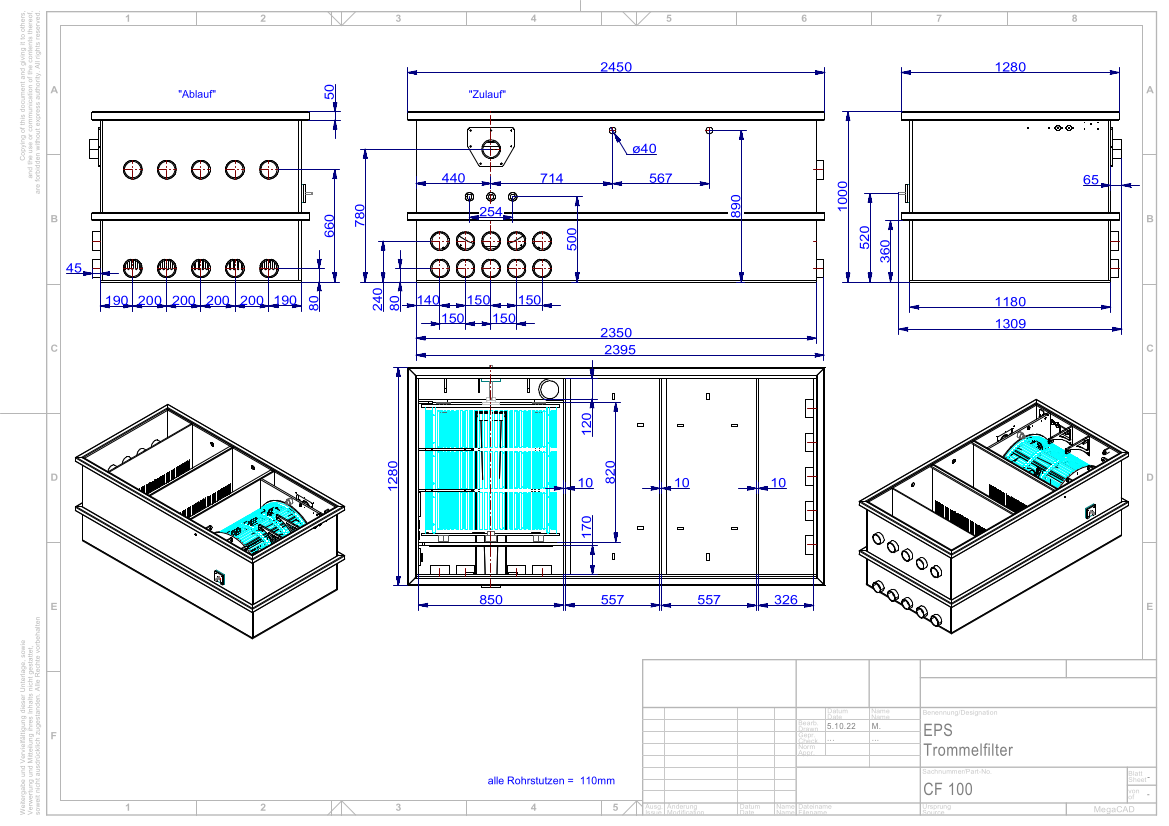

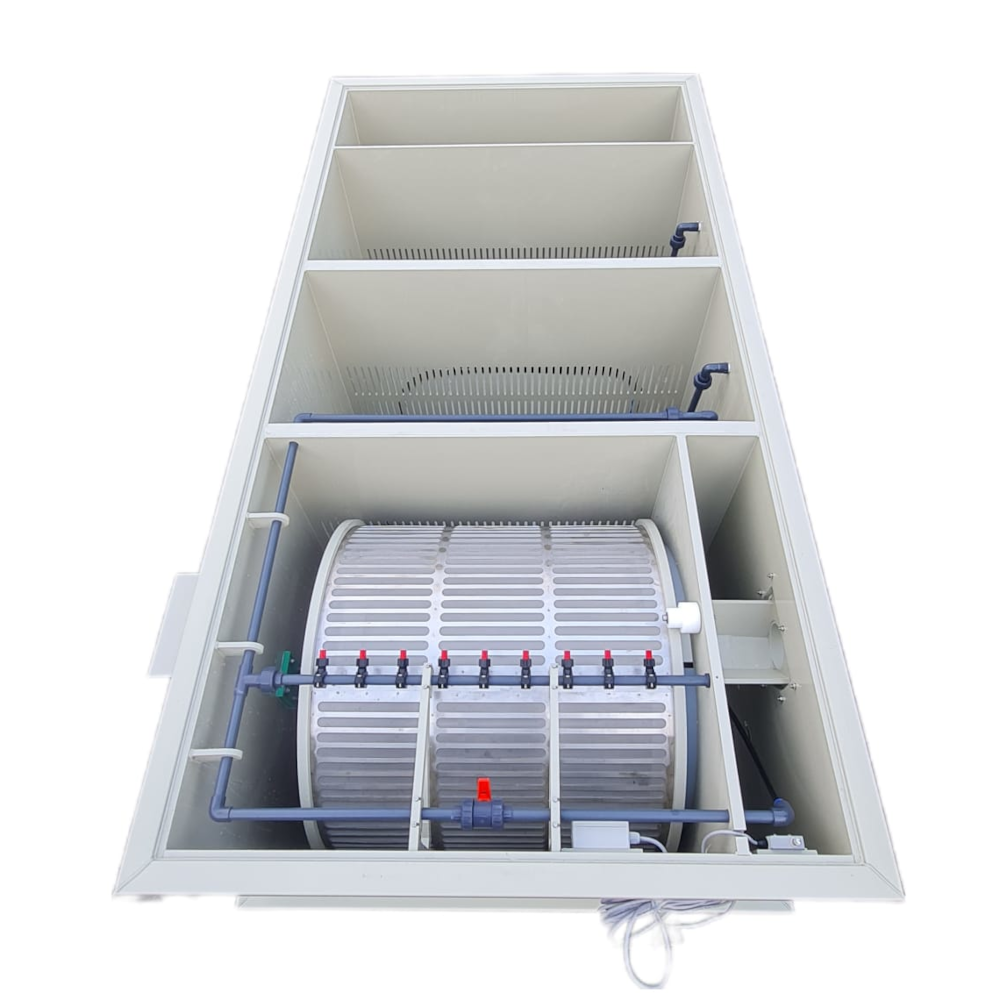

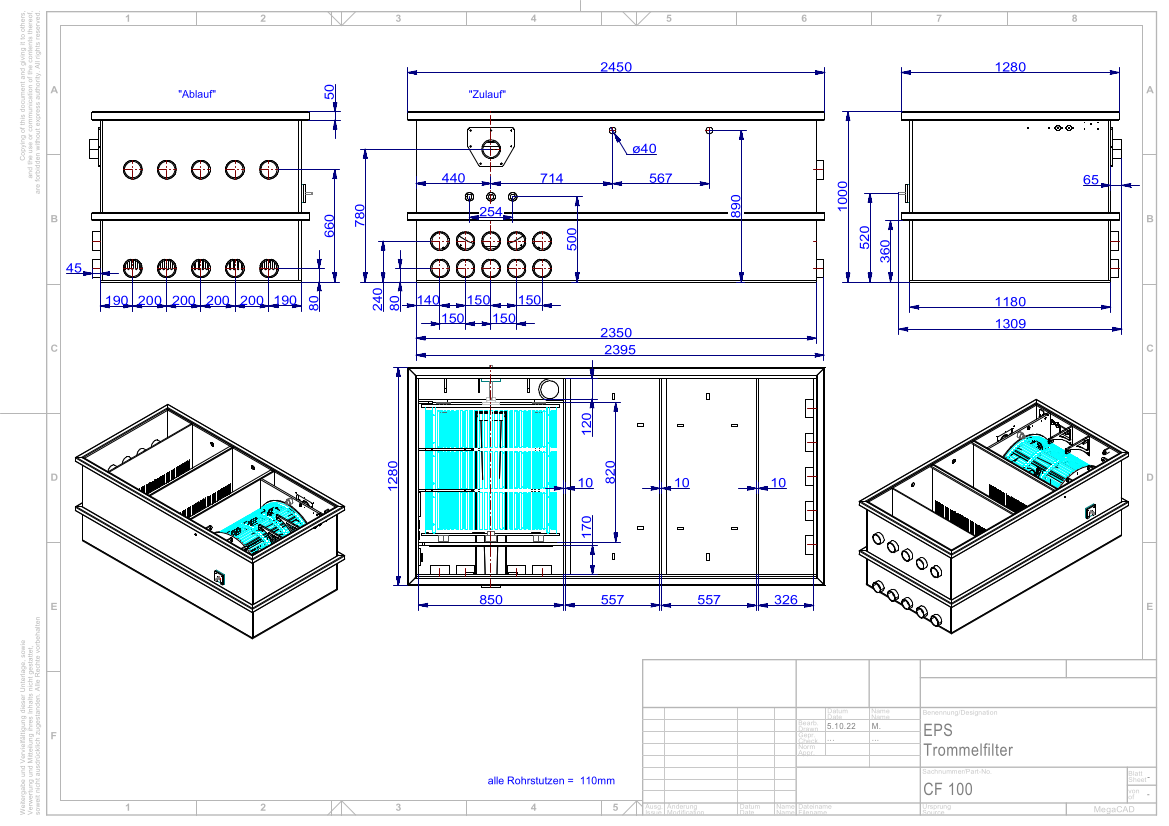

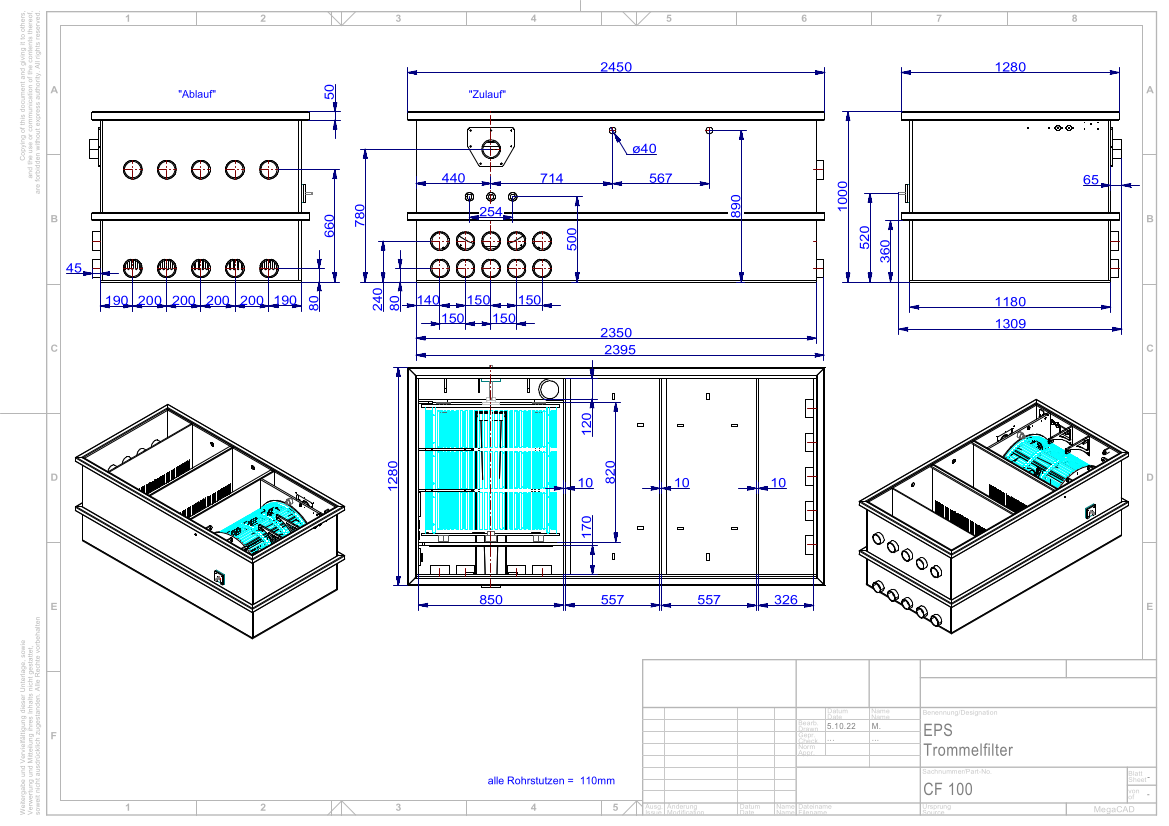

- Dimensions: 245 x 128 x 100 cm

- Material: PP 10 / 15 / 20 mm and 2 mm stainless steel drum

- Installation height with gravity: 17 cm above water

- Stainless steel sieve in sandwich construction

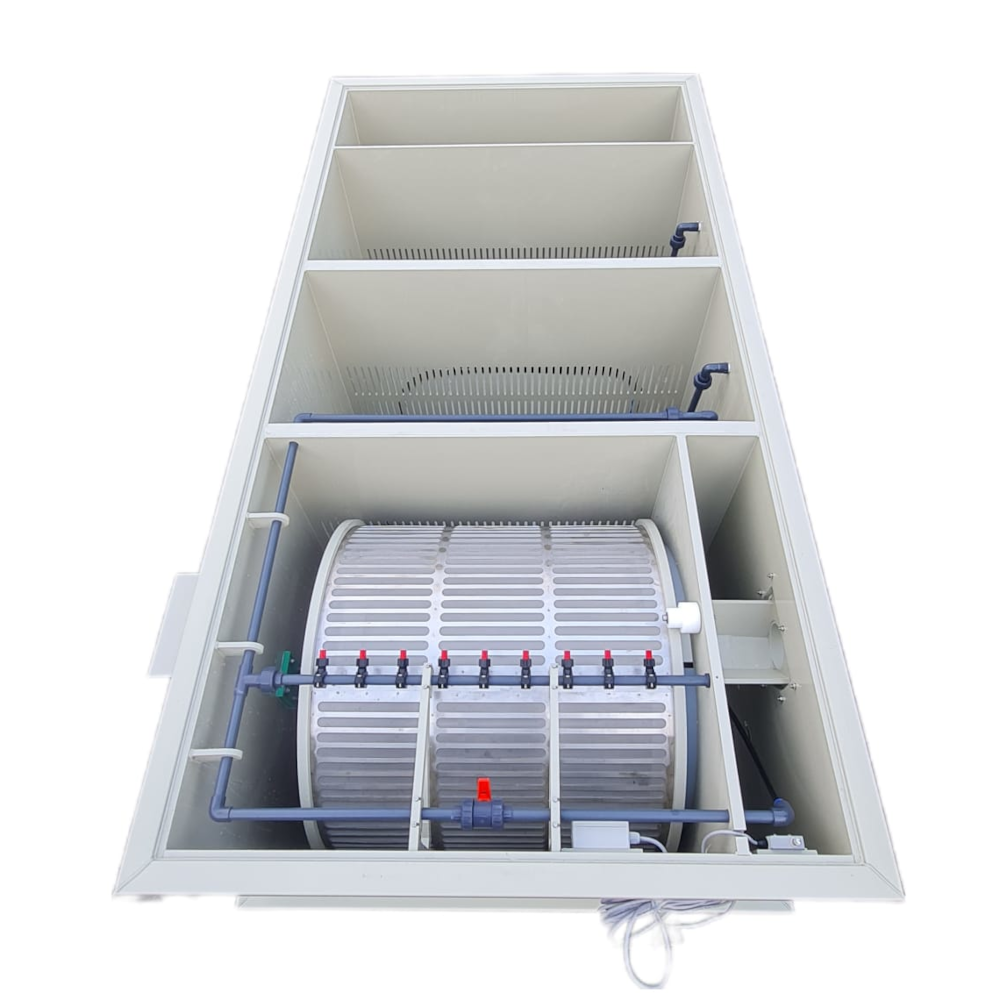

- 2 bio-chambers with Japanese air hose

- Water volume of the 2 bio-chambers: approx. 980 L

- Volume of biomedium: approx. 500 - 600 L

- Integrated pump chamber

- Lid with safety shut-off

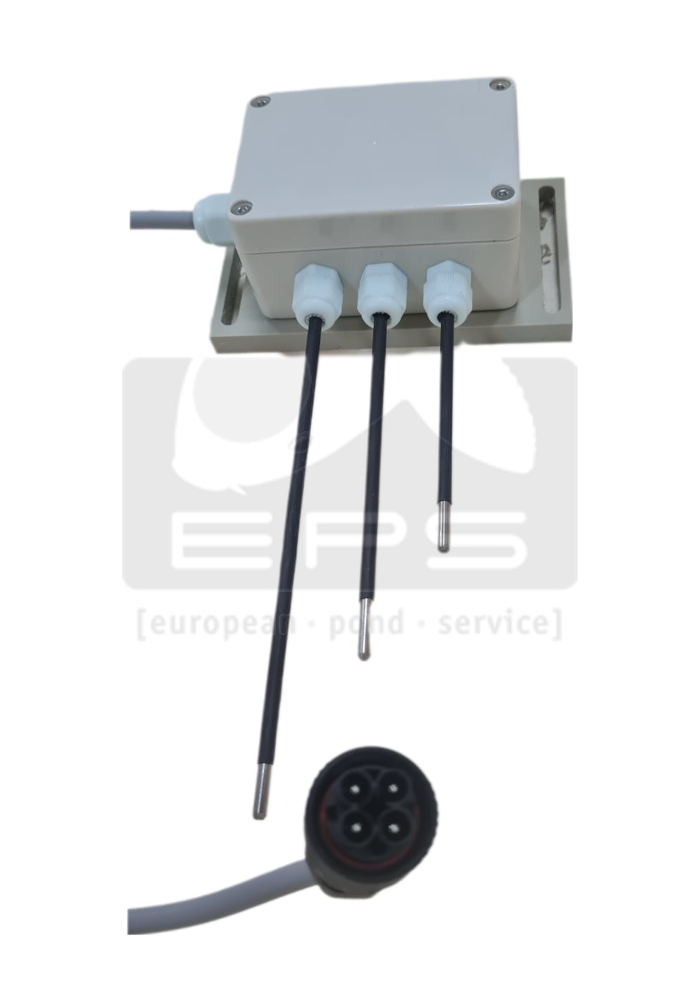

- Plug and Play via sensor with measuring probes

- Rinsing function is triggered by probes, probe level manually adjustable

- Lid switch

- 3x 1/2" internal thread for installation of UVC lamps

- Number of inlets: 10 x 110 mm

- Number of outlets: Pumped 5 x 110 mm

- Number of outlets: Gravity 5 x 110 mm

- Dirty water outlet: 1 x 110 mm

- Rinsing pump: EPS well pump 750 W

- CE mark

- Weight: approx. 180 kg

- Noise level: < 70 db

- Mains voltage: 230V / 50 Hz

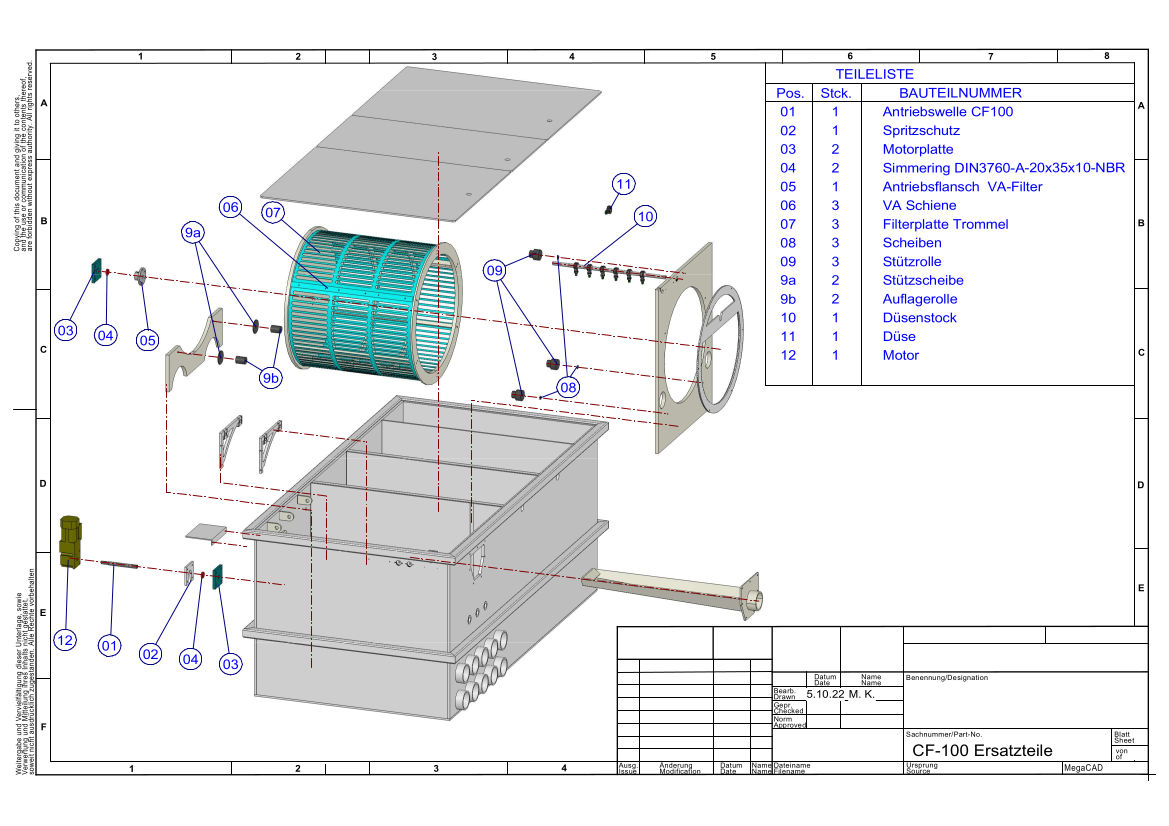

- Removable nozzle holder

- Unscrewable flushing channel

- Incl. manual channel flushing with ball valve

- 2x 90 mm drum bypass

- Incl. six socket connections

(1x drum motor, 1x flushing pump, 3x pond pump, 1x 230V or UVC)

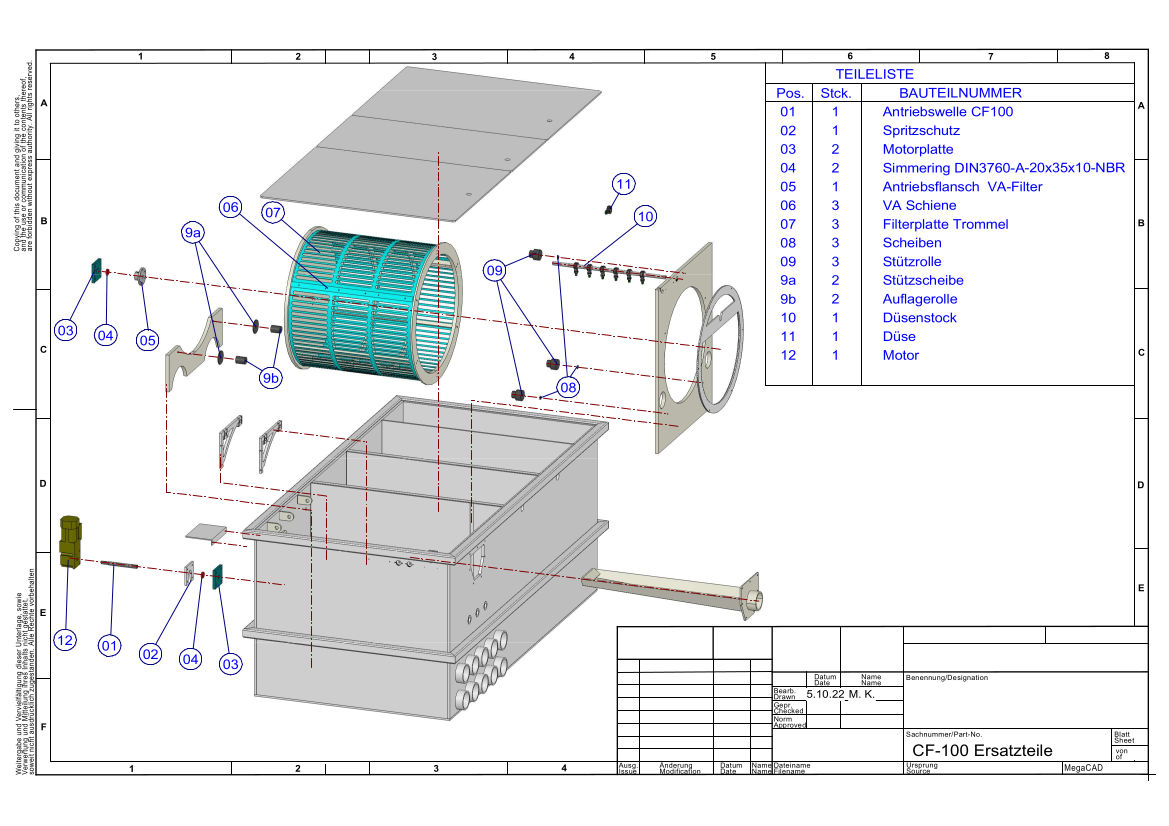

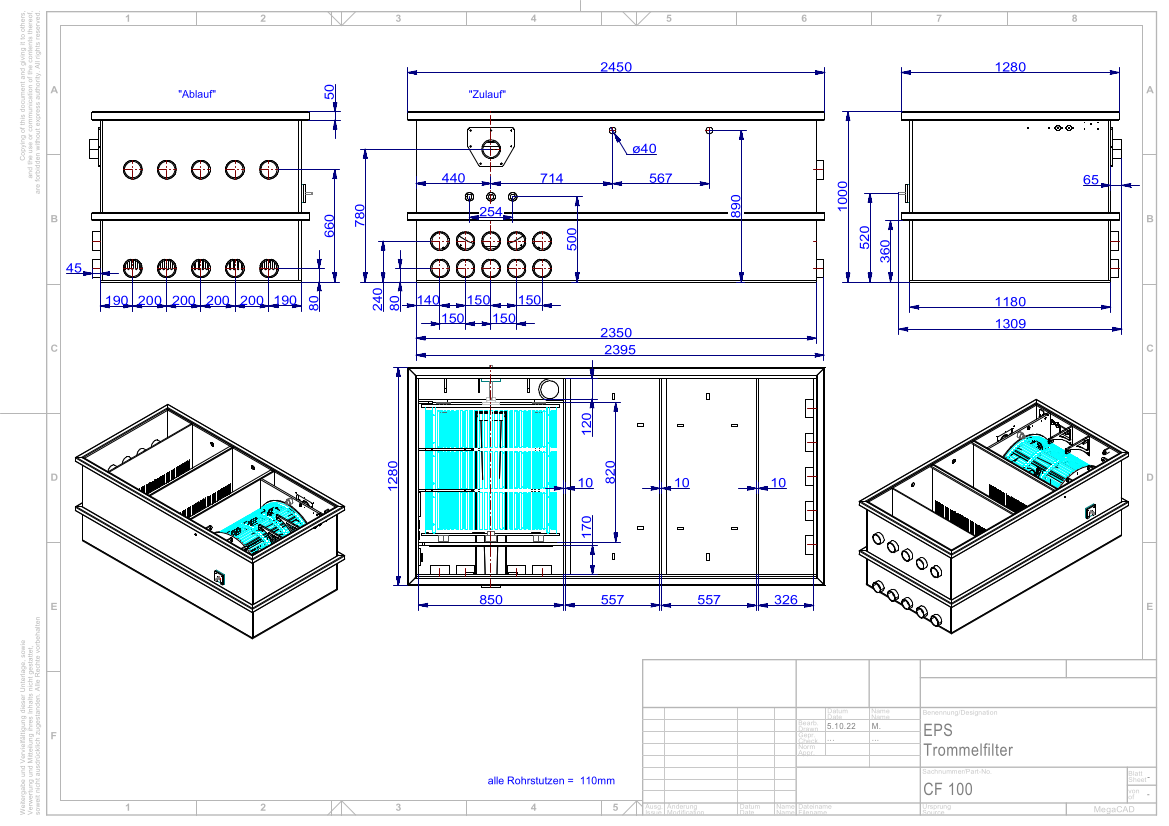

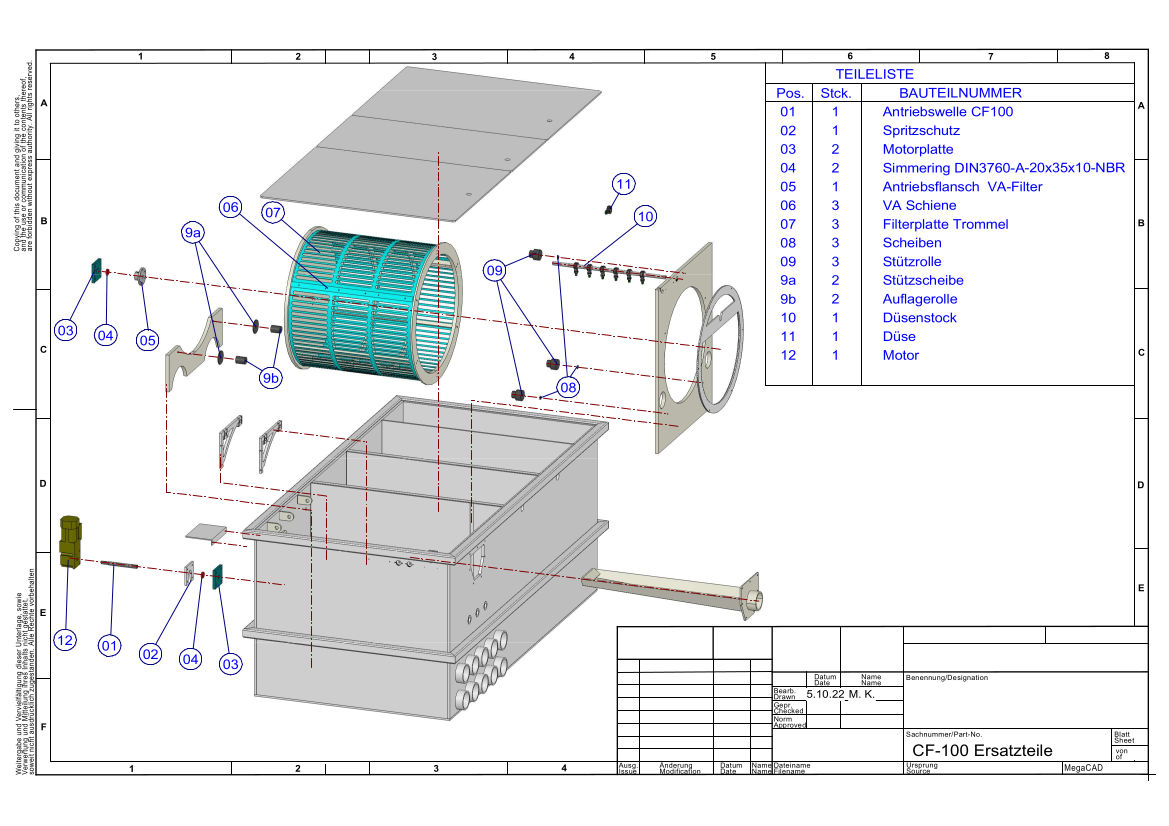

- direct drive from motor to drum with stainless steel shaft

- stainless steel filter panel

- stainless steel mesh 75 micron RVS 316

- flushing times adjustable

- drive motor 220V 60 W 4 rpm

- maintenance key for specialised trade

- operating instructions as well as control instructions are included

- conversion from gravity to pump version is possible in just a few steps ( conversion instructions in the control box )

- warranty: 2 years (the stainless steel strainer is a wearing part and excluded from the warranty)

Function

Due to the high demand, the CF drum filter was built with an integrated pump chamber, biochamber and integrated flushing pump. This means that this drum filter has a plug and play system. On request, we can equip the filter with a submersible UVC and a pond pump according to your wishes. The function of the drum filter is to filter polluted water mechanically. Smallest particles are separated from the water by a stainless steel screen RVS 316 of 75 micrometres and led to the outside via a dirt drain. This filtering process is automatically regulated by a control system and monitored by probes. In the event of a malfunction, the filter automatically switches off the circulation and backwash pump. The water level is constantly monitored by probes. The EPS Combi Drum Filter CF-100 is made of very high quality PP plastic and is supplied including control, emergency cover switch, manual channel flushing, complete piping from the flushing pump to the flushing channel, level regulator, cover and built-in flushing pump in an unprecedented price/performance ratio. All inclusive.

All EPS drum filters are reinforced with a 50/50 U-profile and an inner core of 40/40 4 Kant steel pipe.

The direct drive from the motor to the drum eliminates wear parts such as V-belts, toothed belts or plastic gears.

If the dirty water channel should ever become clogged due to strong filamentous algae or leaves, it is no problem to simply dismantle and clean it without having to dismantle the filter drum or remove the mesh.

In the two integrated biochambers (128 x 55,7 x 100 cm) a Japanese air hose ( 19 mm ) is directly pre-installed for a better "moving bed" process for improved turbulence of the HX 13/17. A diaphragm pump of 100-120 L/min is required for this. We recommend either HAP series, the Secoh series or the AP series.

In addition, the biochamber has been equipped with 8 mm slots to insert HX13/17.

Please note the protected and unprotected surface of the HX13/17. According to this, the square metre of bacteria removal surface is calculated.

The CF-100 drum filter is available in both pump and gravity versions. Even if you have a gravity version, it is possible to convert it to a pump version in just a few steps (if you need help with this, we will be happy to assist you).

Instructions for the conversion are enclosed with the control box.

The fuse function or the emergency lid switch switches off the immersion UVCs directly when the lid is opened. The function is only guaranteed if they are connected via the supplied control unit.

It is recommended that the electrical connection of the control unit is protected by a residual current circuit breaker.

The control unit should not be directly exposed to moisture.

Suitable connection accessories would be Elastomer sleeve 110mm, Elastomer end caps 110mm (if you do not need all inlets and outlets). As UV lamp we recommend our submersible UVC 40 W Amalgan or Immersion UVC 80 W Amalgam.

Due to the use of deep well pumps, a flushing process is hardly audible.

Additional options

- different filter panels (filter mesh) in stainless steel RVS available to order and at extra cost in 43µ or 60µ (please note that with finer mesh the flow rate is 30% to 50% lower depending on the µ-thickness)

- our EPS drum filters can be built individually on request according to drawings at an extra charge

- individual biochambers (round or square) as well as trickle filters can be built on request in all sizes according to drawings

- if you would like individual advice, please feel free to call us on 02945 / 96950

Functions of the control system:

- Plug place for circulation and rinsing pump

- plug and play via sensor with measuring pins

- automatic cleaning

- Switch for on/off incl. emergency switch

- Button for manual flushing

- Flushing is triggered by probes (level of probes adjustable)

- Rotation time/flush time adjustable

- CE mark

- detailed instructions for use are included

- Cleaning is adjustable ( time and duration )

- Dry-running protection for the pond pump

- Dry-running protection for circulation and flushing pump

- Connections for sensor and safety switch

Why EPS drum filters?

after 30 years of experience and many purchased and self-tested filter systems from different suppliers, we decided to build our own drum filter series.

There are stainless steel, PE and PP drum filters on the market.

Some of the stainless steel filters were notable for their poor workmanship (cheap tank connectors that leaked, broke off or had rust defects).

PE filters caused big problems when exposed to sunlight (bending and warping of the material)

Many drum filters do not have a direct drive and are driven by pinions, V-belts or toothed belts.

In our view, these are all weak points that can lead to malfunctions.

For these reasons, we decided to build PP filters that do not deform, are acid-resistant and are operated with a direct drive.

After an intensive test period of approx. 6 years in our own KOI facility, which consists of approx. 60 tanks of various sizes, with full fish stocking and abundant feeding every day, we started series production.

All the problems mentioned are now a thing of the past - We love clear water and healthy fish

EPS drum filters reduce the need for cleaning and maintenance in fish farms and garden ponds to a minimum.

The processing is carried out using the latest technology such as CNC machines, which guarantees quality and precision.

The systems can be used in the koi and/or swimming pond sector as well as in fish farming, industry and public areas.

Dispatch by one-way pallet 220x100x80

The new control system is preset ex works with a water-saving function, whereby the first contact at the probes causes the drum to rotate half a turn without rinsing. At the second contact on the probes, the drum is rotated a full revolution and cleaned completely. This reduces electricity and water consumption.

You can convince yourself of the quality at any time in our showroom

We look forward to your visit

| Article type: | Drum filter |

|---|

Garantiebedingungen Trommelfilter

Defekte und/oder Störungen infolge falscher Installation, Verwendung und/oder Wartung sind von der Garantie ausgenommen.

Die Garantie verfällt, wenn Reparaturen von Dritten durchgeführt wurden.

Die Garantie verfällt, wenn sich die Verkabelung nicht im Originalzustand befindet.

Garantieansprüche werden nur bearbeitet, wenn das Produkt dem Lieferanten franko, zusammen mit einem gültigen, datierten Kaufbeleg vorgelegt wird.

Der Lieferant haftet nicht für Schäden, einschließlich Folgeschäden, die durch falschen Gebrauch oder den Ausfall des Geräts entstehen.

Ansprüche im Zusammenhang mit Transportschäden am Gerät und/oder seinen Teilen werden nur in Bearbeitung genommen, wenn der Schaden dem Händler innerhalb von 24 Stunden schriftlich gemeldet wird.

Diese Garantiebedingungen beziehen sich auf die von uns angebotenen Serienmodelle.

Auf Sonderbauten, die auf Kundenwunsch gefertigt werden, können wir nur Garantie auf

die verwendeten Materialien – die Funktionsweise kann beeinträchtigt sein.

Zubehör

Ersatzteile