€3,450.00*

Available, delivery time: 2-3 Wochen ( bei Versand ins In- und Ausland)

Shipping per industrial pallet 250x100x120

Technical data:

| - Dimensions: 240 x 80 x 92 cm |

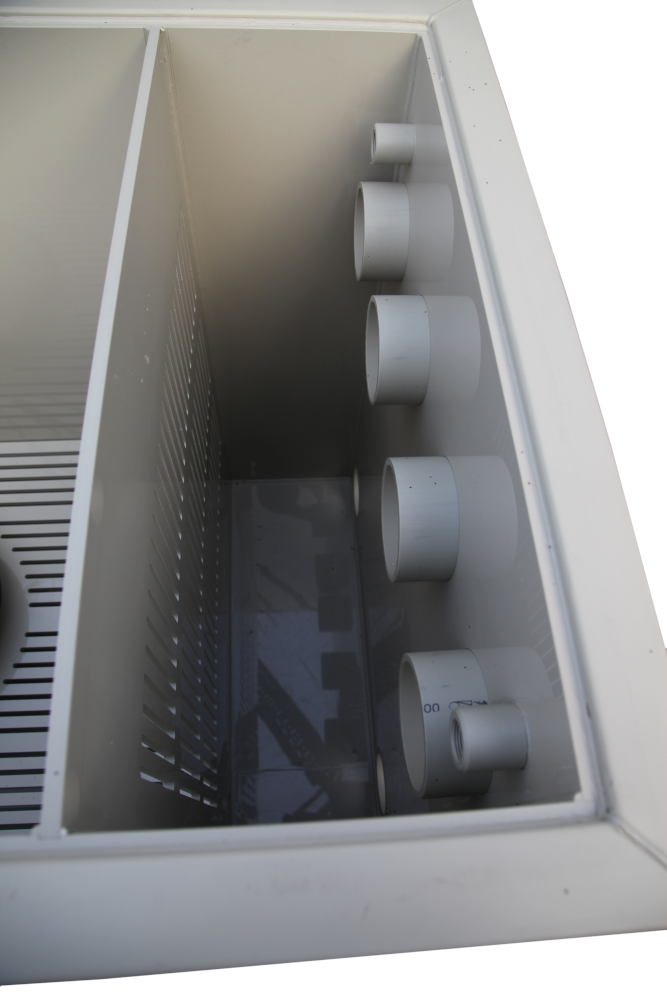

| - Number of inlets: 4 x 110mm |

| - Number of drains: 6 x 110mm |

| - Built-in Japanese 19mm air hose for better movement of the biomedium (Helix) |

| - incl. lid 5mm |

- Dimensions biochamber 1: 102 x 70 x 92 cm

Dimensions biochamber 2: 107 x 70 x 92 cm

This specially developed bio-chamber is suitable for high fish stocking and large food use. The holes in the baffles have a diameter of 12mm, so the biochamber is ideally suited for 13, 15, 17 etc Helix or other filter media. The chamber has been divided with a baffle so that we have two biochambers available and each has a separate membrane diffuser. Each outflow is fed by its own membrane pump. The biochamber can be used as a gravity or pump version. The biochamber is supplied with a lid.

Moving bed filter process is also called fluidised bed process. This process is used in industrial wastewater treatment and in aquaculture systems. In the moving bed process, the filter material is additionally swirled by blowing in air. The filter material is divided into a protected and an unprotected surface.

This means: Unprotected surface is the inner and outer surface of the filter medium. Protected surface means that only the inner surface of the filter material is protected. In the moving bed process, the filter material is moved by air and rubs against each other. This removes the bacteria that have settled on the outside of the filter material. When selecting the filter material for the moving bed process, it is important to pay attention to the protected surface. To prevent high contamination of the filter material, it is very important to use a good mechanical water cleaning system (drum filter, fleece filter, etc.).

Effective turbulence of the filter material is made possible by filling only 40% of the water volume with filter medium. For more information on filter medium here or here.